Offer: 11026-19

Production: Max 5.000 b/h on 0,3 lt cylindrical glass bottle – sparkling water

Bottle diameter: 55-100 mm

Bottle height: 180-350 mm

Inner mouth diameter: min. 18 mm – FILLING VALVE « S »

Rotation: Clockwise

Filling temperature 4°C

The machine is complete with:

– Equipment for one bottle diameter including infeed screw, entry and exit star, filling, capping devices and guides.

– Stainless steel cupboard with the electric control board.

– Motorization by an asynchronous three-phase motor with inverter.

– Electrical height adjustment on filler and capper.

– PLC for standard operations.

– Filling level which can be regulated by changing level pipe.

– Stainless steel support structure. Complete support protection casings in stainless steel with bolt locking.

– Tanks, valves and all parts in contact with the product completely in stainless steel AISI 304.

– Star support in stainless steel. Stars, guides, and bottle-holding rails on stars in polyethylene.

– Protection with window-type openings made up of a boxed supporting frame in stainless steel and transparent polycarbonate.

– All sealing and parts in plastic which touch the product are of materials under existing Directives on the subject.

– The support rests on feet which can be regulated with high resistance steel screws and under screws.

– Stainless steel belt with steel chain with entry and exit at opposite ends of the machine.

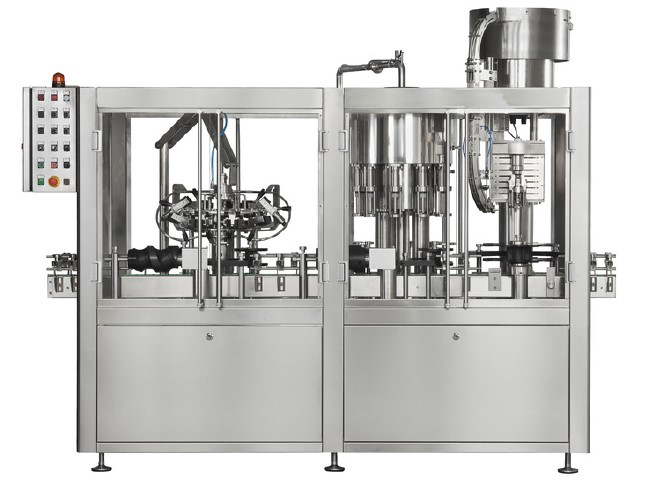

COUNTERPRESSURE FILLER WITH 20 FILLING VALVES

– All components can be easily inspected to simplify all cleaning and maintenance operations.

– The rotary plate, which supports the tank, is connected to the machine base by thrust shoe with a large diameter and orientated by self-lubricating guide bushings.

– The pneumatic cylinders are lifted by compressed air and lowered by a cam.

– The compressed air distribution, which all cylinder are connected to, is adjusted by a suitable self-lubricating reducer.

– The isobaric tank is connected to the rotary hardened plate through its manual adjustable height so that bottles of different sizes can be run despite the limited stroke of the cylinders.

– The filling nozzles bolted to an isobaric tank can be quickly disassembled to allow easy cleaning and maintenance operations.

– The cylinders are equipped with a lowering cam so that, after filling, the bottles are mechanically brought back to the outlet star.

– The isobaric tank, made from thick, strong stainless steel, can work at a pressure of 6 bar (tested in compliance with INAIL (ex I.S.P.E.S.L.) at a pressure of 7 atmospheres). It is complete

with a detachable cover, well-polished on both sides.

– Floating level-control devices are placed on the isobaric cover.

– The container of the filling product is connected to the central distribution system of the filler by a feeding pipe which is fitted with a solenoid.

– The filling valves are fixed to the isobaric tank utilizing bolts which can be easily loosened.

– The centering bottle heads are made from AISI 304 stainless steel.

“S” FILLING VALVE

Compensation, filling and final decompressing with inert gas, suitable for filling all liquids with a pressure level not greater than 2 Bar.

Once the bottle has been placed directly under the filling nozzle, the pressure valve is opened to transfer some of the pressure which is contained in the tank of the liquid to the empty bottle.

When the pressure in the bottle is the same as the pressure in the tank, the nozzle is opened by a spring to start the filling cycle.

The liquid which goes into the bottle is spread along its sides by a rubber packing mounted on the leveling system.

As soon as the liquid reaches the hole on the leveling system the filling nozzle is shut off mechanically by a control cam to isolate the bottle from the pressure of the tank.

Once the liquid in the bottle has been leveled, a control cam opens the valve for reducing the pressure inside the bottle.

Finally, the bottle, now filled with liquid both still and leveled, is brought to the outlet star.

The CAPPER TURRET 4 HEADS AROL “VA” is constructed in steel and equipped with safety

devices and is suitable for inserting one format of aluminum screw cap in glass bottles

– The caps are fed through an automatic system.

– The caps travel down a stainless steel descending slide to the distribution head which places them on the container opening.

– The threaded heads insert the caps.

– The automatic feeder is completed with a cap chute duct and catching head system.

Copyright © 2024 All Rights Reserved