OFFER: 11893-20

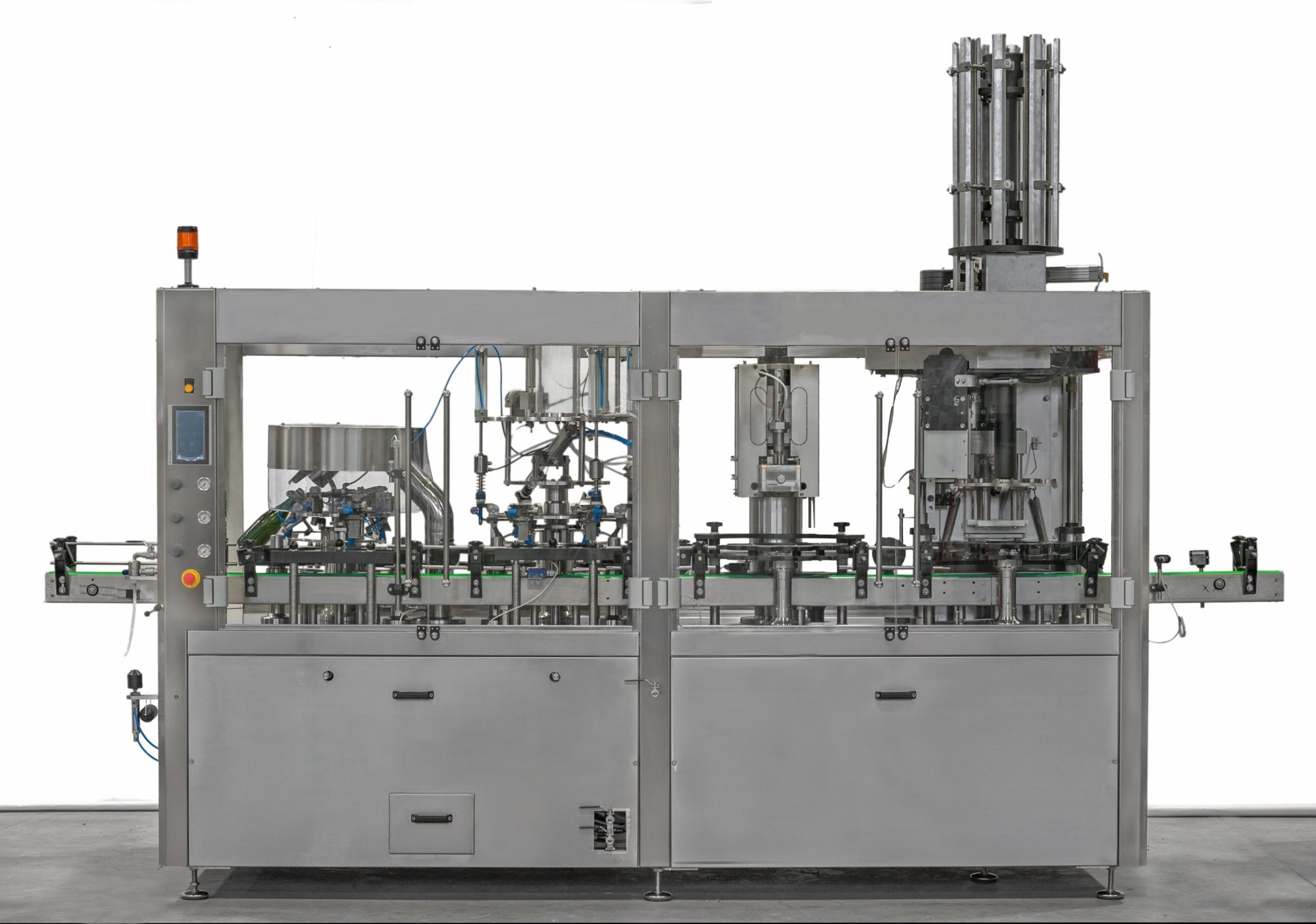

The automatic monoblock is designed to perform disgorging, liqueur’s dosage, leveling, corking, and wire hooding.

Output: 900 bottles per hour

The automatic monoblock is composed of four turrets: the first one with continuous rotation, the second one with an intermittent rotation, the third is the corker, and the fourth is the wire holder.

Working cycle:

The first turret is designed for the disgorging operation. It is equipped with three groups to seize and close the bottle.

During the workflow, it reverses the bottle by around 65°, and then it removes the crown cap. The bottle without the cap remains raking, and it is closed to limit the quantity of wine coming out. Before the end of the rotation, the bottle returns to a vertical position to move on the conveyor belt.

The second turret has six working stations, each one with grippers. It carries out three operations during one rotation: the sediment ejection (the bottle remains in vertical position), the dosage of the liqueur (the bottle reversed at 65° as in the first turret), and the leveling (this operation performed after the bottle has returned in the vertical

position).

Between the first and the second turret, there is a device detecting the presence of the crown cap.

The first turret is also equipped with a device for the discharge of caps into a tray located inside the chassis. The tray is extractible to allow periodical emptying. The upper part has a belt conveyor and a device for loading and discharging the bottles; these are called inlet and release starwheels and guide conveyors. The bottles are transported overrun

surfaces from the belt conveyors to the turrets.

All parts in direct contact with the product are in stainless steel AISI 304, approved for the food industry.

Technical Features:

Bottle height: 230 – 380mm

Bottle diameter: 70 – 113mm +/-2

Voltage: 380Volt -3phases – 50Hz

Auxiliary Tension: 24 Volt – 50Hz

Total Power: 3,90 kW

Compressed Air: 430 Lt/h

Weight: 2400 Kg

Copyright © 2024 All Rights Reserved