OFFER : 9675-17

Liquid to be bottled: Spirits

Bottle type: Cylindrical and shaped bottles

Type of closure 1st closing turret: Gpi closure (max speed 1500 bph)

Type of closure 2nd closing turret: Bar Top cork (max speed 2500 bph)

Output in bph: 2800 max

Output in lt/ph: 2200 max

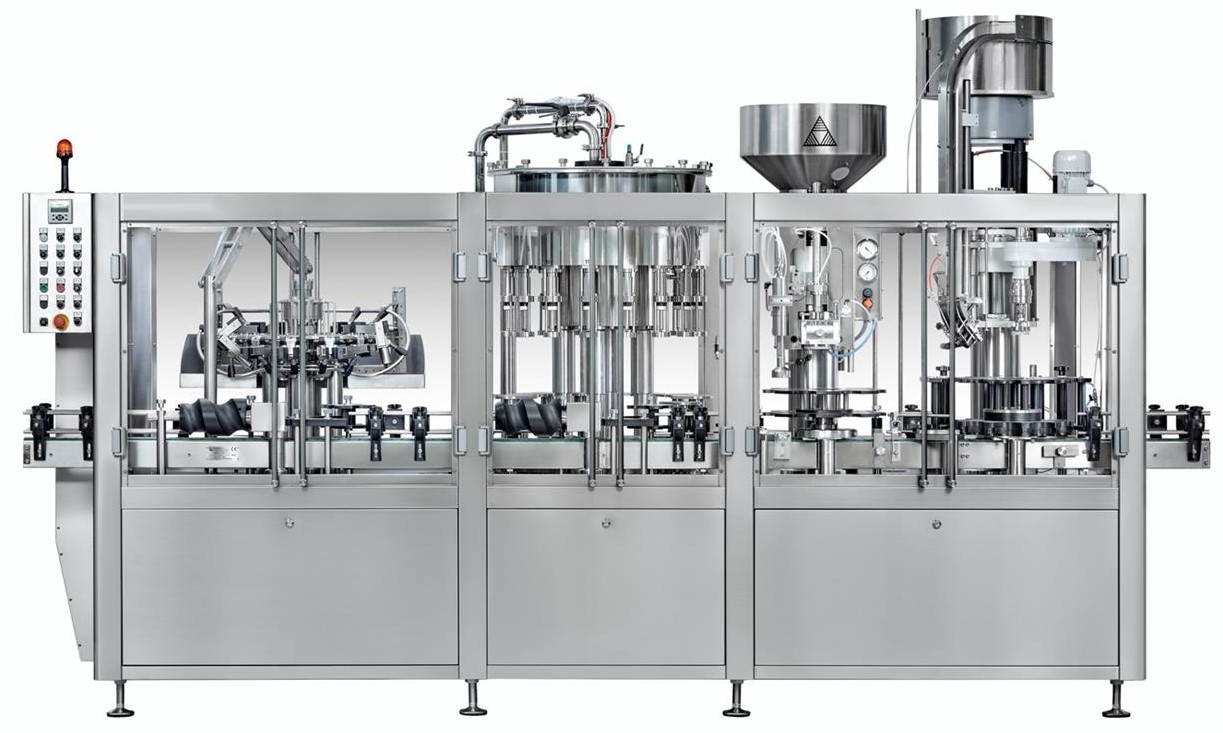

TYPE OF MONOBLOCK: RINSING 9 GRIPPERS – FILLING 8 VALVES – CAPPING 1-HEAD

MODEL: 12-16-1-1 VP-PP

VARIABLE SPEED DEVICE: ELECTRONIC VARIATOR (INVERTER)

TYPE OF RINSER: MOD. TECNA 12

TYPE OF GRIPPER: BY TWIST

NUMBER OF GRIPPERS: 12

RINSING LIQUID: WATER (MAX TEMPERATURE 50°C)

TURRET LIFTING: ELECTRICAL

LIFTING CYLINDERS: PNEUMATIC

FILLING SYSTEM: BY GRAVITY

N° OF FILLING VALVES: 16

LIQUID THAT CAN BE USED: SPIRITS

MAX PRODUCTION IN BPH: 2.500 x 0.75 lt (1.500 WITH GPI CLOSURE)

FIRST CAPPER FOR PLASTIC CAP: FUTURA VP (AROL BRAND)

NUMBER OF CAPPING HEADS: 1

TYPE OF CAP: GPI SCREW CAP

CLOSING HEAD: WITH VACUUM

CAP FEED: BY MEANS OF A VIBRATING SYSTEM

FIRST CAPPER FOR PLASTIC CAP: FUTURA PP (AROL BRAND)

NUMBER OF CAPPING HEADS: 1

TYPE OF CAP: BAR TOP

CLOSING HEAD: WITH VACUUM

CAP FEED BY MEANS OF A VIBRATING SYSTEM

DIAMETER OF THE BOTTLES: MIN/MAX 55/110 mm

HEIGHT OF THE BOTTLES: MIN/MAX 180/360 mm

MAIN TECHNICAL AND CONSTRUCTIVE FEATURES

– Chassis of the machine in sturdy mechanical carpentry completely clad in stainless steel AISI

304 with wide lateral access doors

– Safety guards in compliance with the CE norms with panels of plastic material and safety

micro-switches

– Parts in contact with the liquid of stainless steel AISI 304

– Power transmission by means of gears

– Inlet and outlet star-wheels with safety devices

– Electrical system in compliance with the international safety norms with low voltage controls

contained in a stainless steel box

1. RINSER TURRET: 12-GRIPPER RINSER

– Mechanical movement through gears

– Adjustable production speed

– Liquid distributor equipped with blocking device in case of missing bottles

– Adjustment of the rinsing and dripping times

– Rinsing liquid pressure regulator

– Bottle overturning with TWIST system

2. FILLING TURRET: 16-VALVE FILLER

– Parts in touch with the liquid in stainless steel AISI 304

– Pneumatic lifting cylinders with air pressure lift and descent with cam.

– Tank height adjustment device for the format change

– Power transmission by means of gears

– Bottle inlet by means of a screw

– Inlet and outlet star-wheels with safety devices

– Liquid feed pipe with pneumatic ball valve in stainless steel AISI 304 for the control of the liquid

flow in the container

– Control of the liquid in the tank by means of probes or level relays

– Outlet of the feeding pump controlled from the control board

– Valves easy to demount for cleaning and maintenance

– Tank with rounded bottom for the total discharge of the liquid

– Ball valve for the total discharge of the liquid contained in the tank

– Electrical system in compliance with the international safety norms with low voltage controls

contained in a stainless steel box.

– Filling with GRAVITY system

3. FIRST CAPPING TURRET (GPI CAPS)

– Vibrating hopper for cap selection

– Cap chute with detection photocell

– Pick&Place system for picking up the cork from the cap chute and positioning it under the

closing head

– Screwing head with vacuum system for keeping the cork

– Manual lifting for format change

4. SECOND CAPPING TURRET (BAR TOP CORKS)

– Vibrating hopper for cap selection

– Cap chute with detection photocell

– Pick&Place system for picking up the cork from the cap chute and positioning it under the

closing head

– Closing head with vacuum system for keeping the cork

– Manual lifting for format change

Copyright © 2026 All Rights Reserved