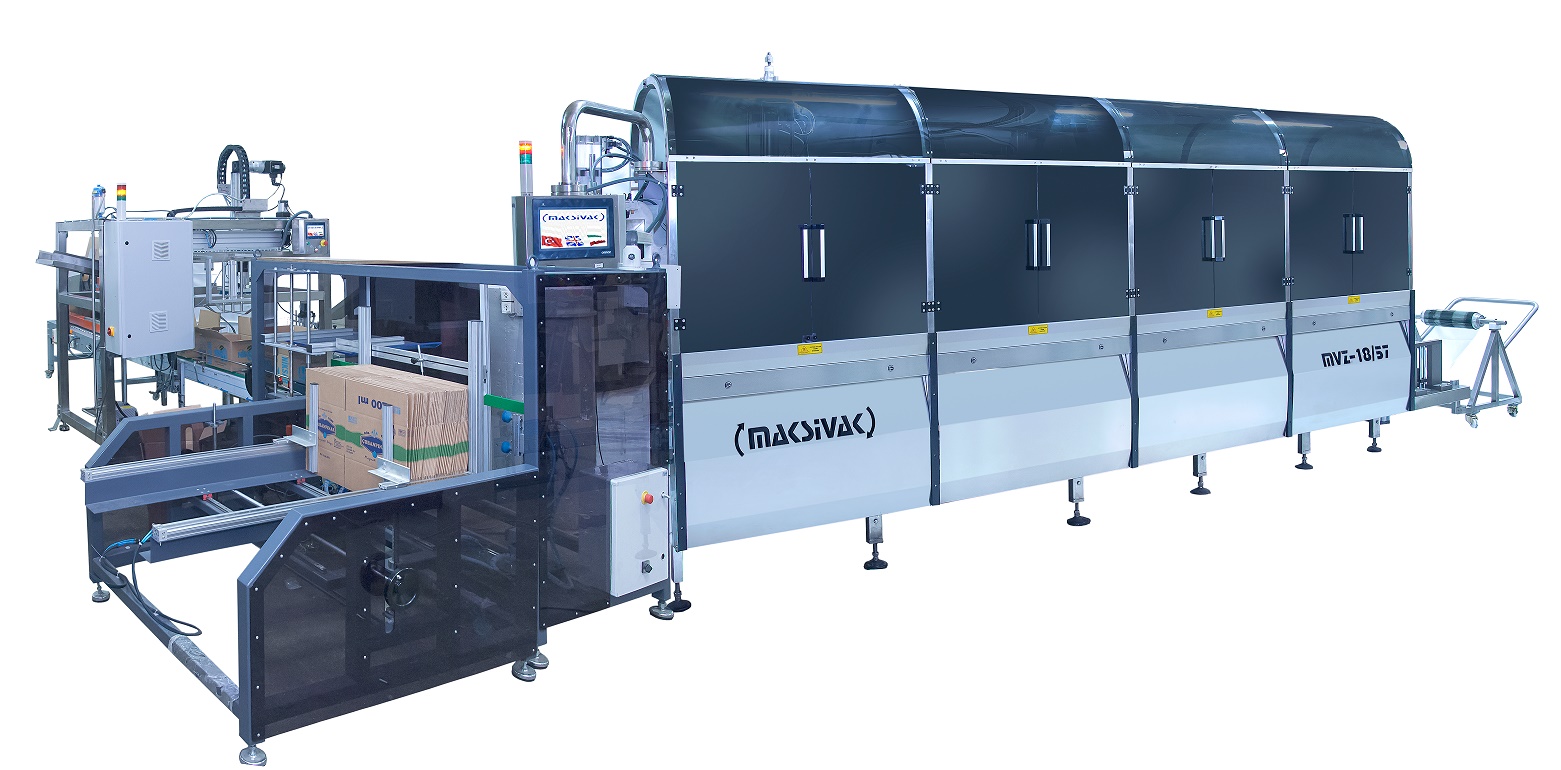

WATER CUP MACHINE WITH LESS WASTGE

MVZ-18/57

Capacity: 10,000 cups/hour

Via our machine’s eccentric cutting system, the same amount of plastic

cup production can be accomplished with minimized gaps less pitch

and foil width. According to the current machines in the industry, it

saves % 3.125 from the bottom foil and %5.55 from the top foil.

In other companies, while installing new coil or if there is a problem

with foil, it is required to pull foil along the machine to take shape

again. This causes waste of time and waste of foil up to the length of

the machine.

With the chain system used in our machine, the shape can be taken

immediately by feeding foil to the chain and the production can

proceed. In this way you can save time and foil.

The progress of foil on machines with pulling system is provided by

pulling the foil along the entire machine with holding it from one point.

This makes foil very sensitive to the factors like warming- cooling,

having different rigidity and elongation- shortening because of these,

slips occurs on pitches. Stations needs to be set again continuously.

Via chain system used in our machine, the progress of foil is connected

to the speed of chain so it is not affected from foil’s physical alterations.

Prolapsing of the foil to the middle is minimized by holding it from

edges via chain. In this way, positioning can be done more reliable.

Because of inability to perform this with pulling system machines, there

can be seen differences between plastic cups on the middle and edges.

The progress of foil is dependent on mechanism in the pulling system

machines and due to mechanism structure there is a high potential risk

of mechanical faults.

Application Areas:

– Water

– Fruit Juice

– Airan

– Ice

Copyright © 2024 All Rights Reserved